TKS Pro Engineering is a trading and production company in the field of fire protection. The company develops and implements innovative fire extinguishing technologies that are far superior in efficiency to foreign counterparts. The proposed technologies meet all requirements and standards in the field of firefighting.

With a focus on quality and reliability, TKS Pro Engineering ensures that every solution is tailored to protect lives and property effectively.

Gas-Powder Fire Extinguishing Technology

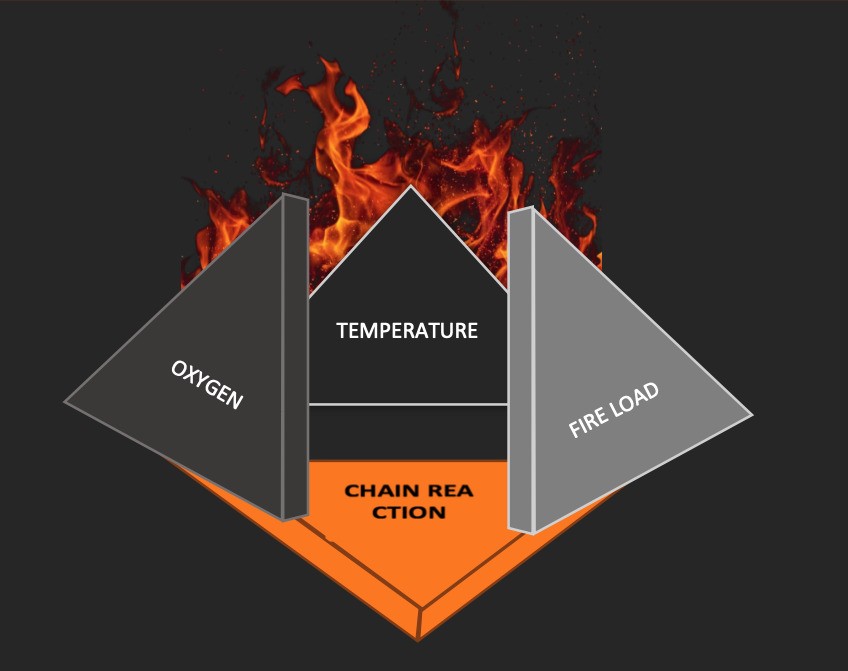

Gas Fire-Extinguishing Functions

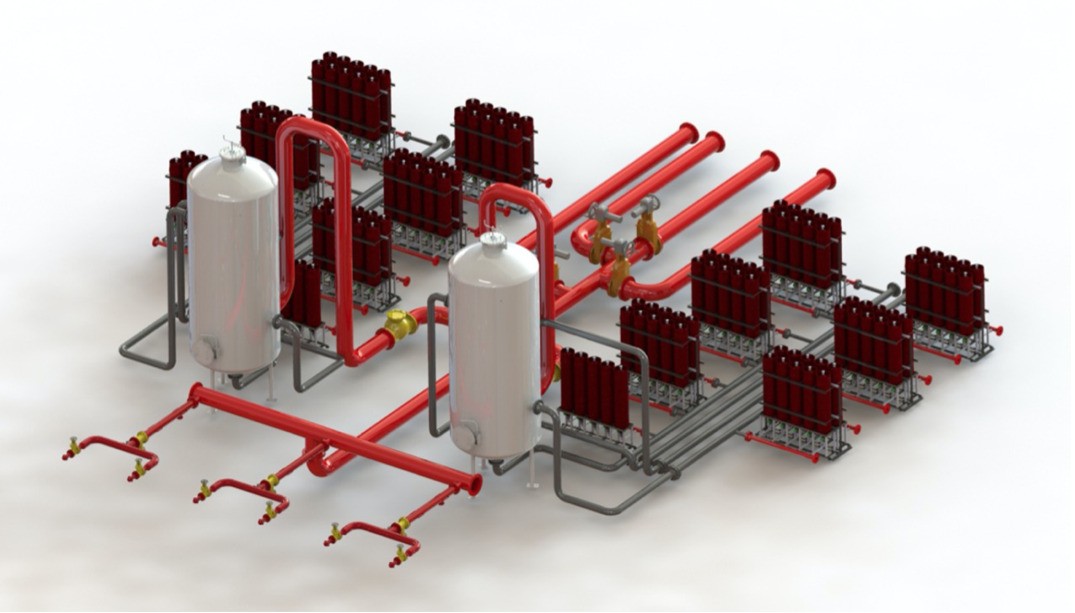

Gas-powder fire extinguishing modules

| Parameters | DEFII 100 | DEFII 10 | DEFII 5 | |

|---|---|---|---|---|

| Protected volume | Class A: 900 m3 B: 600 m3 | Class A: 90 m3 B: 60 m3 | Class A: 60 m3 B: 45 m3 | |

| Fire class | А, В, С, Е | |||

| Extinguishing agent | Gas powder | |||

| Operating temperature range | -50°С to +50°С | |||

| Total weight of the module | 365 kg | 37 kg | 20 kg | |

| Weight of the extinguishing powder | 80 kg | 6 kg | 3 kg | |

| Weight of the working gas (liquid CO2) | 30 kg | 3 kg | 1.8 kg | |

| Extinguishing agent jet range | 18-20 m | 5-6 m | 5-6 m | |

| Release time of the extinguishing agent | 10 s | 15 s | less than 5 s | |

| Dimensions (W x D x H) | 753 x 730 x 1732 mm | 415 x 235 x 800 mm | 255 x 225 x 750 mm | |

| Lifetime | 20 years* | 20 years* | 10 years* | |

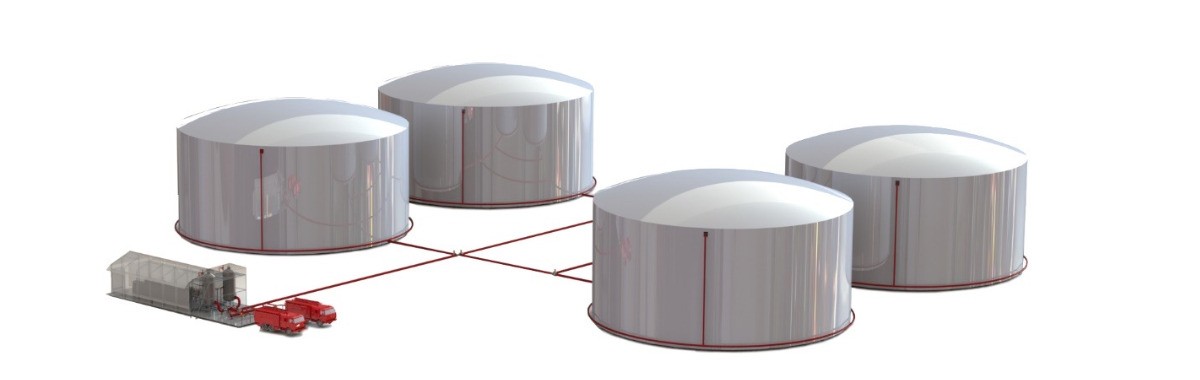

Protection of tanks and storage facilities

Installation with separate powder hopper and cartridges with carbon dioxide cylinders. This installation is used to protect vertical steel tanks (VST) and vertical steel tanks with pontoon (VSTP) with a storage volume of 2,000 m3.

Technology Advantages

Economic Efficiency

Protected Objects

Mobile System for Extinguishing Oil, Gas and Oil and Gas Fountains

Tornado KFX

The gas-powder extinguishing system is designed to extinguish oil and gas fountains with a flow rate of around 10,000 m3/day (for oil) and 10,000,000 m3/day (for gas). The unit is a block container that can be installed on various chassis. Possibility to refill the unit on site.

| Main technical parameters | Unit |

|---|---|

| Total quantity of gaseous extinguishing agent in the system | 2200 kg |

| Weight of the extinguishing powder | 1600 kg |

| Mass of carbon dioxide CO2 | 600 kg |

| Extinguishing powder discharge time | 20 to 30 sec |

Technical Requirements for the Production System

Industry

Metalworking, assembly, storage workshops Industrial area

3000-5000 square meters

1-2 floors

Not less than 7 m (on the 1st floor)

500 kW

Heating, water, waste water

from 3 t (min. 2 pcs.)

from 4.2 m

Concrete, smooth, 5t/sqm

solid / insulated sandwich panels

Winterproof

200-300 square meters

500 square meters